Fluoropolymer Lined Advantages:

- High corrosion resistance

- High resistance to mechanical impacts

- Product residues can easily be detected

- High optical contrast to product

- Highly reflective

FLUOROPOLYMER LINED

Fluoropolymers are a class of olefinic, thermoplastic polymers where some or all of the hydrogen has been replaced by fluorine. The result is either a fully fluorinated polymer such as PTFE and PFA, or a partially fluorinated polymer, such as ECTFE. This type of polymers has very high resistance to chemical corrosion in the most acidic and alkaline environments, for this reason and also because of the high temperature resistance, they are widely used in the chemical industries.

These coatings are applicable on the inner surfaces of chemical industry equipment such as tanks, columns, pipes, fittings and valves. Of course, coating method; due to the nature and condition of any of fluoropolymers and also corrosive environments and equipment design, Should be determined by our experts.

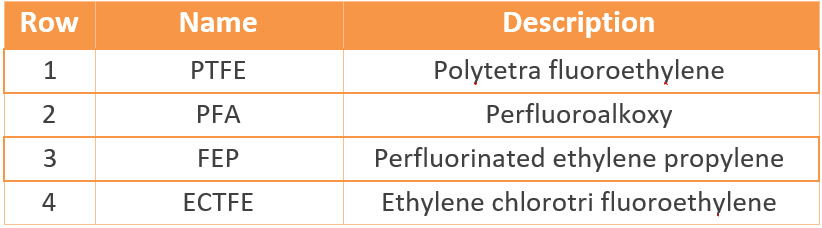

Fluoropolymer types which are used in the Shimi Azar Jaam as a coating on the internal surfaces of equipment are as follows:

Fluoropolymer Lined Advantages:

- High corrosion resistance

- High resistance to mechanical impacts

- Product residues can easily be detected

- High optical contrast to product

- Highly reflective

Overall fluoropolymers show extraordinary resistance in all acidic and alkaline environments and they are resistant up to 270°C (Depending on the type of fluoropolymer and chemical environment).

Evaporation & Crystallization

ECTFE, a copolymer of ethylene and chlorotrifluoroethylene, is a semi-crystalline melt processable partially fluorinated polymer. It is availa

Chemical Industries

FEP (Fluorinated Ethylene Propylene) is another melt-processable Fluoropolymer. It does not have the almost universal chemical resistance of PTFE and PFA ...

PFA Lining

PFA (Perfluoroalkoxy) was developed in order to achieve a true melt-processable fluoropolymer. Its characteristics are such that in service it can be ...

PTFE Lining

PTFE (Polytetrafluoroethylene) is a non-stick fluoropolymer coating that has the highest operating temperature of any fluoropolymer and has extremely low ...